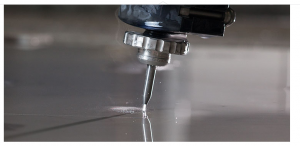

Vested Metals now offers Waterjet cutting services. Unlike many alternatives Waterjet machines can cut a wide range of metals including titanium, stainless steel, aluminum and most other specialty metals.

To get a quote for your project or to learn more contact us at 904-495-7278 or at info@vestedmetals.net. Vested Metals has material in stock, ready to be cut and shipped.

Benefits of Waterjet Cutting Services

Highly versatile: Waterjet machines can cut most metals and material up to 18 inches thick. Alternative methods including plasma and laser cutting have a more limited scope.

Tighter tolerances:

- Some material/thickness: .001″ (0.25 MM)

- For materials over 1 inch thick the machines will produce parts from +/- 0.005 to 0.100 inch (0.12 to 2.5 mm)

Clean edges, no burns: In addition to cleaner cuts, the benefit reduces the need for secondary processing (faster cutting, lowering cost).

Waterjet Cutting Mechanics

Waterjet cutting is a supersonic erosion process. As pressure goes up, the speed of the Waterjet stream increases. After the stream of water exits the orifice, the velocity is what determines the cutting speed. At 40k PSI the jet velocity is over 1,600 mph (mach 2) and has a jet width of 0.60. At 90k PSI the jet velocity increases to over 2,500 MPH (mach 4) and the jet width drops to 0.030. It is worth noting that the smaller width implies that less abrasion is required during the cutting process.

Also, for perspective, pressure ranges on the low end from 10k PSI all the way up to 75K+ PSI (very high pressure). Most jobs are done using 40k or greater PSI. According to Flow, anything over 75k PSI is consider HyperPressure. Advanced systems can run at >90k PSI.

You can learn more about metal cutting from the following links:

- Flow: the advantages of cutting metals with Waterjet

- Video: Flow machine in action cutting aluminum

Waterjet vs. Other Technologies

Waterjet cutting can be favorably compared to 3 other cutting technologies:

1) Plasma – Uses a high temperature ionized gas to burn/melt material:

- Secondary processing includes slag grinding for the removal of the heat affected zone (HAZ) and flattening to remove distortion from heat. There is generally no secondary processing for Waterjet cutting.

- Materials that plasma can cut include primarily stainless steel and aluminum. Waterjet cuts almost all material.

- Thickness goes up to 2-3 inches versus Waterjet’s 24 inches.

- Accuracy is up to 0.10 inch versus Waterjet’s 0.001 inch.

2) Laser – Uses a concentrated light beam to melt material:

- Secondary processing sometimes includes the remove of oxidized edge and heat affect zone (HAZ).

- Materials are generally limited to stainless steel and aluminium.

- Thickness is generally under 1 inch.

- Accuracy at 0.001 matches Waterjet’s 0.001.

3) EDM – Uses an electrical discharge to erode material:

- Like Waterjet cutting, there is generally no secondary processing.

- Materials cut need to be conductive.

- Thickness is generally under 12 inches.

Waterjet History

High-pressure water was used for erosion in the 1800s by the mining industry. However, it wasn’t until the 1930s that narrow streams of water were using for cutting material. Initially, paper was the primary material used. The Paper Patents Company of Wisconsin, for example, designed a cutting machine that horizontally cut sheets of paper.

In its current form, Waterjet cutting was first developed in the early 1970s to cut soft materials such as paper, plastic and foam. In the early years, jet speed was under 1,500 MPH but gradually increased to over 2,000 MPH by the late 1990s. In the 2000s, speeds increased to over 2,500 MPH. According to Flow speeds are expected to increase by another 25-30% in the next 5-10 years.

The higher speeds allow machines to cut harder materials including stone, metals and ceramics. Note again that high speed Waterjet machines can cut most materials including most metals (titanium, stainless steel, aluminum, etc.).

Other advances in Waterjet technology relate to multi-axis cutting. 5-axis cutting systems were first developed in the 1980s by Ingersoll-Rand but had significant limitations. By the 2000s, 5-axis cutting significantly expanded the range of materials available for cutting.

Conclusion

Vested Metals is excited to be able to offer Waterjet cutting services using a Flow machine. Contact us at 904-495-7278 or at info@vestedmetals.net to learn more about how we can help. Vested Metals has material in stock, ready to be cut and shipped.