Custom 630 (17-4 PH) Project 70®+

Custom 630 (17-4 PH) Project 70®+ was developed by Carpenter Technology as an improved-machining version of the convention martensitic precipitation/age-hardening stainless alloy offering high strength and hardness along with excellent corrosion resistance. According to Carpenter Technology, with Custom 630 (17-4PH) Project 70®+, 15% higher machining speeds can be achieved with improved finishes and longer tool life. Custom 630 (17-4PH) Project 70®+ is used in a variety of applications including medical instruments, chemical processing equipment, gears, nuclear reactor components, and jet engine parts.

The material is typically supplied from the mill in the annealed condition, however, Custom 630 (17-4 PH) Project 70®+ is often heat treated.

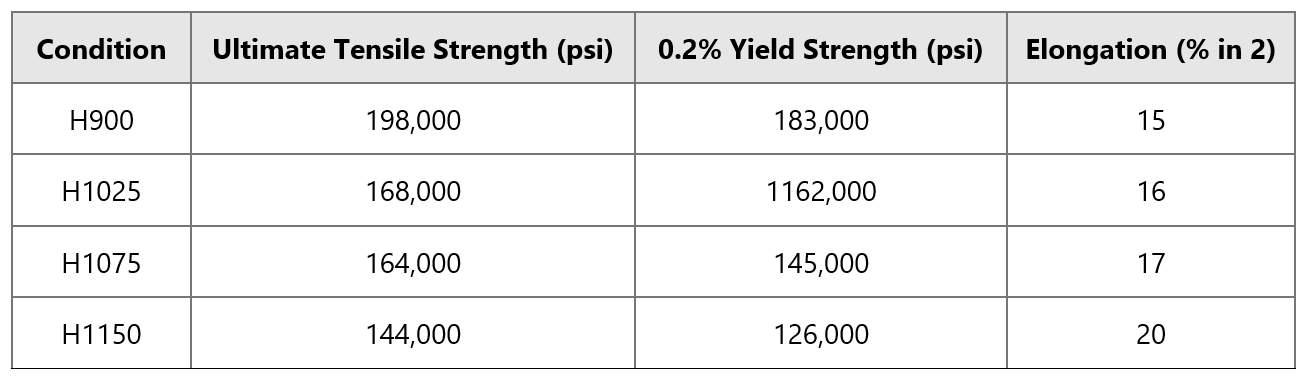

Common heat treatment conditions and approximate mechanical properties for 17-4 PH

Custom 630 (17-4 PH) Project 70®+ has good machinability. In the annealed condition Custom 630 (17-4 PH) Project 70®+ machines similarly to 304 and the machinability improves as the age-hardening temperature increases.

In most environments Custom 630 (17-4 PH) Project 70®+ corrosion resistance is superior to that of 400 series hardenable stainless steels and approaches corrosion resistant levels of 302 and 304.

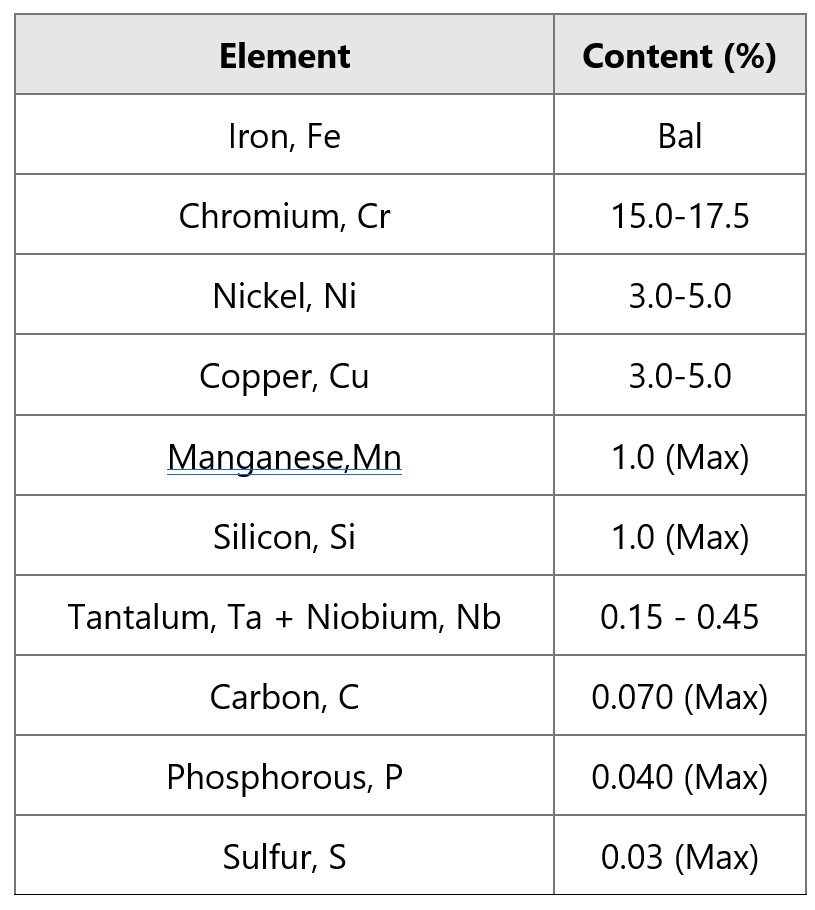

Chemical Composition of 17-4 PH

Specifications include ASTM A564, ASTM F899, AMS 5643, ASME SA564.

Custom 630 (17-4 PH) Project 70®+

| Specs | Markets | Applications | Forms |

|---|---|---|---|

| ASTM A564, ASTM F899, AMS 5643, ASME SA564 | Medical, Aerospace, Industrial | Aerospace structural parts, Surgical & dental equipment, Firearms | Bar |

GET IN TOUCH

For more information about our products, to request a quote, or ask a question, please contact us using the form below.

LET’S GET STARTED

Vested Metals is headquartered in sunny Florida and serves customers throughout the world. Get in touch with us today, we look forward to working with you.

OUR LOCATIONS

Corporate Headquarters –

St. Augustine, FL – Sales and Service Center

- 7000 US Highway 1 North, Suite 504, Augustine, FL 32095

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]

Sales Office –

Fort Wayne, IN – Sales Office

- 1690 Broadway, Building 19, Suite 165, Fort Wayne, In 46802

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]