316/316L

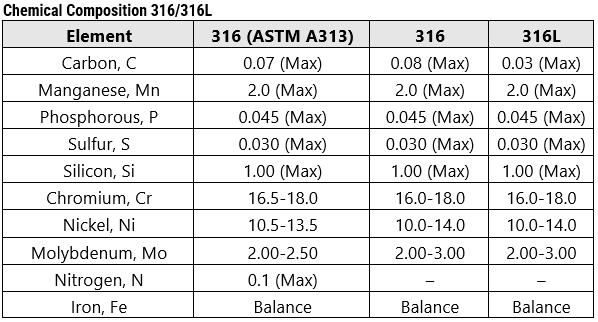

316 and 316L are austenitic stainless steels with corrosion resistance that is superior to that of other 300 series stainless steels such as 304, 303, 302, and 347. The primary difference between 316 and 316L is that 316 can have a carbon content of 0.08% (or 0.07% for ASTM A313) while the carbon content of 316L is limited to 0.03%. The L in 316L stands for low carbon.

Specifications:

ASTM A313 (Spring Wire), ASTM A276 (Bars and Shapes), ASTM A240 (Plate), ASTM A479 (Bars and Shapes used in Boilers and other High-Pressure Applications), ASTM A314 (Billets and Bars for Forging).

Applications:

316 and 316L are used in paper pulp handling equipment, equipment used in the production of photographic chemicals, inks, bleaches, dyes, and various high temperature equipment applications.

Additional Information:

316/316L is not magnetic in the annealed condition. However, it becomes slightly magnetic after cold working or welding.

316/316L can be hardened by cold working. It does not harden by heat treatment.

316/316L and 316L Project 70+ Summary Information

| Specs | Markets | Applications | Forms |

|---|---|---|---|

| ASTM A313 (Spring Wire), ASTM A276 (Bars and Shapes), ASTM A240 (Plate), ASTM A479 (Bars and Shapes used in Boilers and other High-Pressure Applications), ASTM A314 (Billets and Bars for Forging) | Medical, Aerospace, Industrial | 316 and 316L are used in paper pulp handling equipment, equipment used in the production of photographic chemicals, inks, bleaches, dyes, and various high temperature equipment applications. | Bar |

LET’S GET STARTED

Vested Metals is headquartered in sunny Florida and serves customers throughout the world. Get in touch with us today, we look forward to working with you.

OUR LOCATIONS

Corporate Headquarters –

St. Augustine, FL – Sales and Service Center

- 7000 US Highway 1 North, Suite 504, Augustine, FL 32095

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]

Sales Office –

Fort Wayne, IN – Sales Office

- 1690 Broadway, Building 19, Suite 165, Fort Wayne, In 46802

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]