Stainless Steel Custom 465® Round Bar

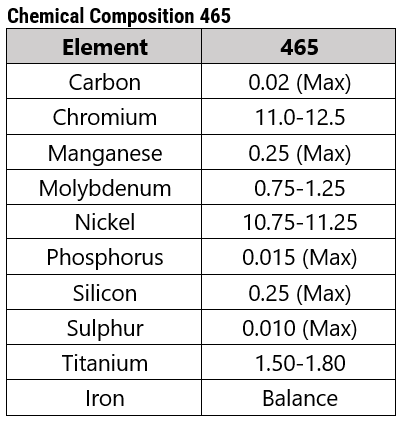

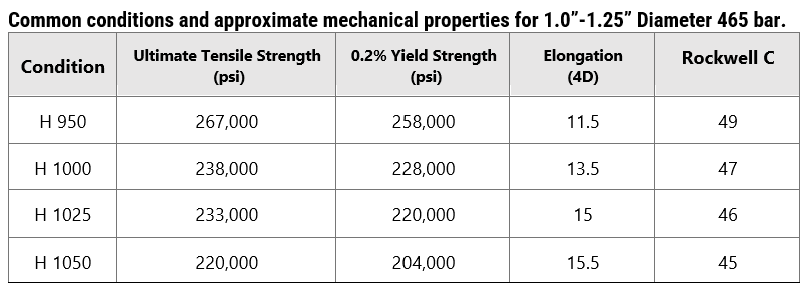

465/Custom 465® is similar to 455 in chemistry and that is a martensitic age-hardenable alloy. When 465/Custom 465® is cold worked before heat treatment the strength is greater than that of 465/Custom 465® heat treated from the annealed condition. 465/Custom 465® has excellent corrosion resistance. 465/Custom 465® is a Carpenter Technology registered trademark.

Vested Metals stocks stainless steel Custom 465® round bar in a range of sizes.

Common Applications

Drill bits, drivers, torque shafts, orthopedic and dental instruments

Specifications

ASTM F899, AMS 5936, ASTM A564, ASTM A693, UNS 46500

Custom 465® Summary Information

| Specs | Markets | Applications | Forms |

|---|---|---|---|

| ASTM F899, AMS 5936, ASTM A564, ASTM A693, UNS 46500 | Medical, Aerospace, Industrial | Drill Bits, Drivers, Torque Shafts, Orthopedic and Dental Instruments | Bar |

GET IN TOUCH

For more information about our products, to request a quote, or ask a question, please contact us using the form below.

LET’S GET STARTED

Vested Metals is headquartered in sunny Florida and serves customers throughout the world. Get in touch with us today, we look forward to working with you.

OUR LOCATIONS

Corporate Headquarters –

St. Augustine, FL – Sales and Service Center

- 7000 US Highway 1 North, Suite 504, Augustine, FL 32095

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]

Sales Office –

Fort Wayne, IN – Sales Office

- 1690 Broadway, Building 19, Suite 165, Fort Wayne, In 46802

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]