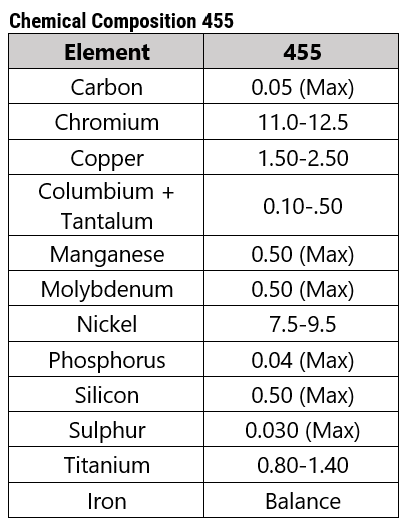

Custom 455® Stainless Steel

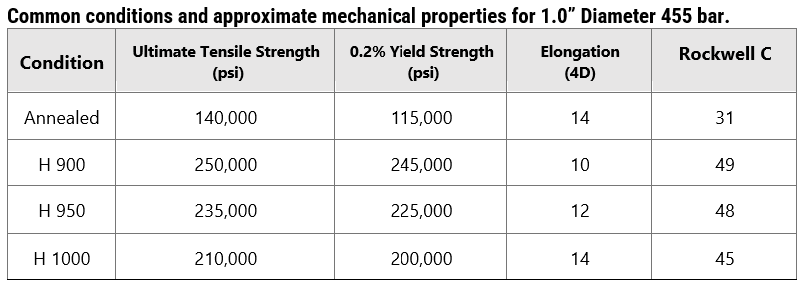

In the annealed condition 455/Custom 455® is relatively soft, however with a single heat treatment it is capable of very high strength, just below that achieved by 465/Custom 465®. Cold working 455/Custom 455® before aging will enhance the strength versus aging from the annealed condition. 455/Custom 455® also has excellent corrosion resistance, similar to 465/Custom 465®. 455/Custom 455® is a Carpenter Technology registered trademark.

Common Applications

455/Custom 455® is one of the most widely used stainless steel grades for surgical instruments because of its high tensile strength and resistance to corrosion in fresh water. However, in contrast to other grades, 455/Custom 455® is not an implantable metal. Instead, it is primarily used for various surgical instruments including but not limited to surgical scissors, ear pins, rollers and guides.

Material Characteristics

ASTM F899, AMS 5617 (Bar, Forging and Wire), AMS 5860 (Plate, Sheet, and Strip), ASTM A465, ASME SA564, ASTM A693 (XM-16), AMS 5672 (Wire), MIL-S-83311, UNS 45500

Custom 455® Summary Information

| Specs | Markets | Applications | Forms |

|---|---|---|---|

| ASTM F899, AMS 5617(Bar, Forging, and Wire), AMS 5860 (Plate, Sheet, and Strip), ASTM A564, ASME SA564, ASTM A693 (XM-16), AMS 5672 (Wire), MIL-S-83311, UNS 45500 | Medical, Aerospace, Industrial | Needles, Pins, Drill Bits, Drivers, Torque Shafts, Orthopedic and Dental Instruments | Bar |

GET IN TOUCH

For more information about our products, to request a quote, or ask a question, please contact us using the form below.

LET’S GET STARTED

Vested Metals is headquartered in sunny Florida and serves customers throughout the world. Get in touch with us today, we look forward to working with you.

OUR LOCATIONS

Corporate Headquarters –

St. Augustine, FL – Sales and Service Center

- 7000 US Highway 1 North, Suite 504, Augustine, FL 32095

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]

Sales Office –

Fort Wayne, IN – Sales Office

- 1690 Broadway, Building 19, Suite 165, Fort Wayne, In 46802

- Phone:(904) 495-7278

- Fax: (904) 621-9299

- [email protected]