Before launching into an overview of how titanium supply is produced, take note of the latest titanium 3D printing application – custom bicycles. New Zealand-based 3D printing company RAM3D produced a 3D printed road bike with the help of custom bike producer Sturdy Cycles. The titanium parts used to create the custom bike were heat treated to reduce stress during the fabrication process.

Although a specific price for this bike hasn’t been announced it is safe to assume it will be fairly expensive. Based on BikeRadar, the best titanium bikes can cost well over $5,000. The high price is due not just to the 3D printing but also the cost of titanium.

Titanium Production Process Overview – Why Titanium Is Expensive

For a titanium supplier to produce any kind of titanium, titanium must be removed from ore which is typically accomplished using the Kroll process. Once the ore is removed, vacuum arc remelting can begin which is typically where the alloying process occurs. A titanium supplier at this stage has the opportunity to create a wide range of grades which have various advantages and disadvantages depending on the applications. In the case of Ti 6Al-4V, for example, aluminum and vanadium are added at this stage.

Remelting is followed by forging, casting and heat treatment. Forging uses thermal and mechanical energy on titanium billets or ingots to cause the material to change shape. Heat treatment is then applied in an alpha beta alloy followed by annealing, stress relieving and solution treating/aging.

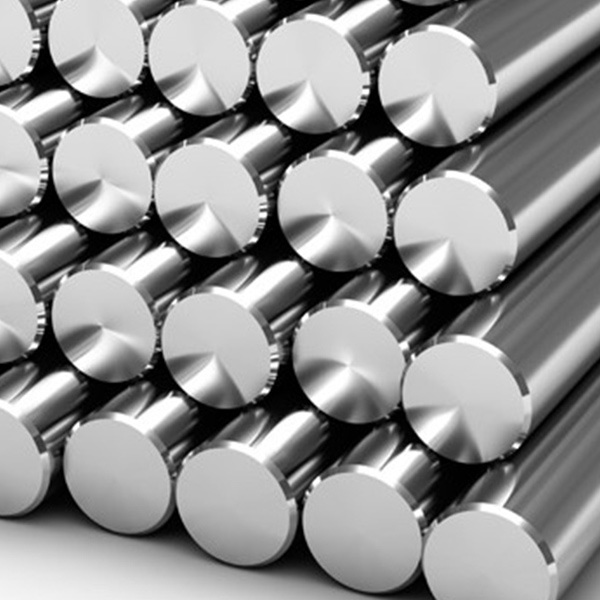

Once the titanium is properly treated it can be fabricated into a wide range of shapes including plate, sheet, tube, bar or wire.

Regardless of shape or grade, Titanium is a common choice when a high strength to durability ratio is needed for a specific application. However, because the production process is so long and complex, titanium tends to be more expensive than other specialty metals including stainless steel aluminum, and cobalt.

Call Vested Metals at 904-495-7278 if you are interesting in working with an experienced titanium supplier or e-mail us at [email protected].